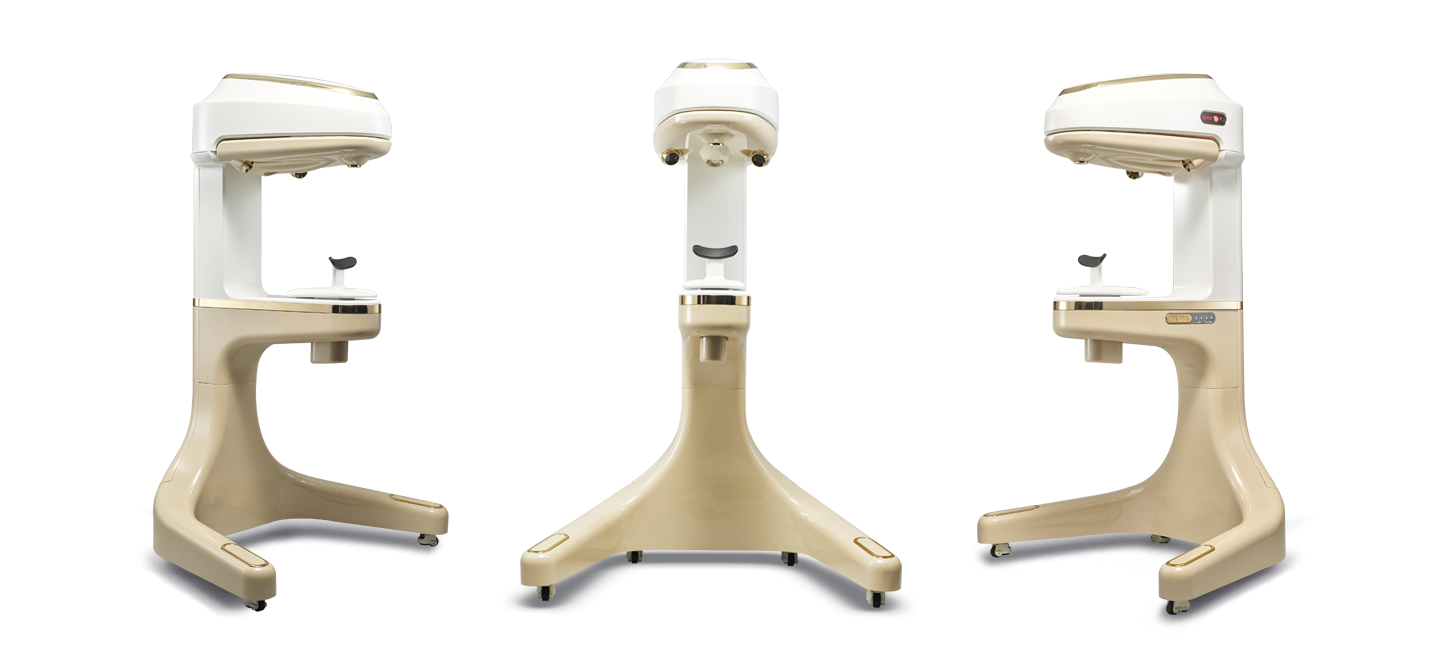

3D Scanner

We make the most customized products with cutting edge technology

The wigs are made through obtaining precisely customized solutions that are ideal for every person. In the same

way that everyone’s fingerprints are unique,

everyone’s heads vary in size and shape. Therefore, it is important to precisely measure the heads for

comfortable and natural wigs.

We accurately measure the head shape and the extent of hair loss for each customer with our 3D scanners and

create a model that is identical to the customer's

head through the use of an automated molding technique. We provide a distinctive wig that perfectly matches each

and every one of our customers.

why 3d scanner

In 2002, Hi-MO introduced the 3D scanner system for the first time in the industry and

continued development through R&D to measure the head shape more accurately.

wig production process

The measured data is transmitted to our factory in real time. With the automated

molding technique, a model that is the same as the customer's head shape is carefully manufactured.

-

3D Scanner

-

Product Manufacturing

-

Product Fitting

-

measuring method

While the customer remains seated,

the 3D scanner’s rotates 360 degrees

for a rapid and accurate measurement.

-

Accuracy

Computerized measurements

allows accurate measure -

Time required

for the measurementThe measurement is completed

with in 15 seconds. -

Time required

for the productionThe data transmitted in real time through the

ERP system enables the automated

molding technique to be used, there

by reducing the time required for the production.

SPECIFICATION

| Dimensions (W x D x H) | 44.09” x 27.56” x 68.50” cm |

|---|---|

| Weight | 84 kg |

| Scanning Time | 15 sec |

| Scanning Method | Laser Triangulation |